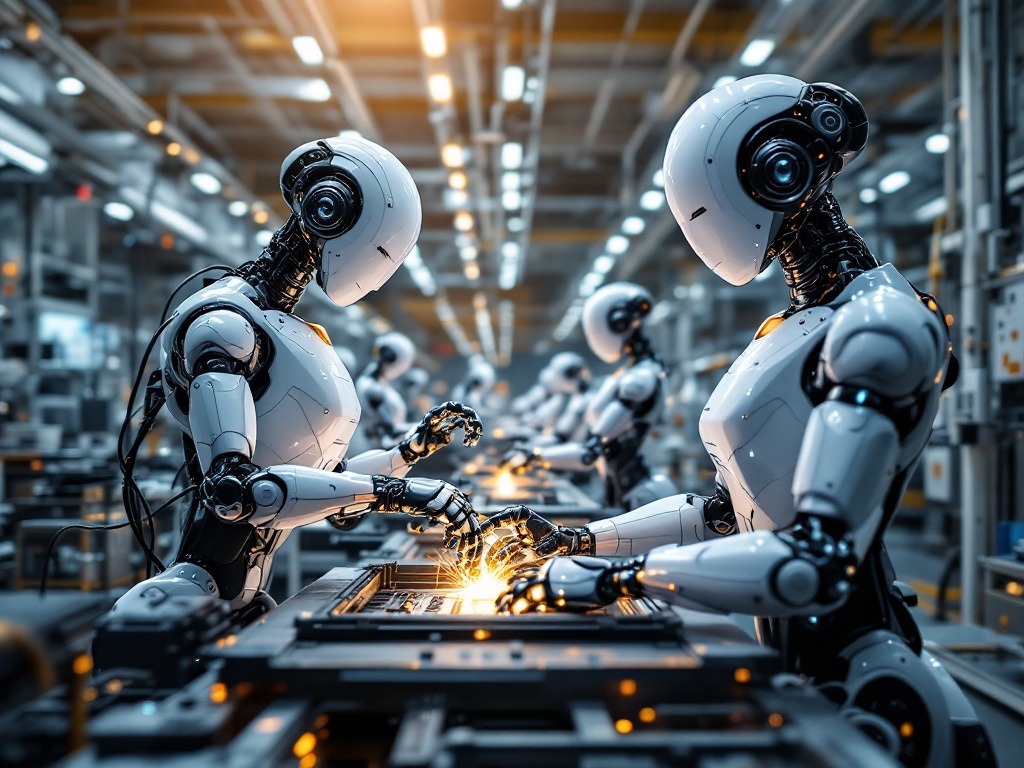

As we move into 2024, the manufacturing industry is witnessing a significant transformation driven by the rapid advancement of robotics technology, particularly in the realm of collaborative robots or “cobots”. At ChiJay Infrastructure Solutions, we’re excited to explore how these innovations are reshaping the manufacturing landscape and enhancing productivity. Let’s dive into the latest trends and developments in collaborative robotics for 2024.

1. The Rise of Artificial Intelligence and Machine Learning

One of the most significant trends in 2024 is the integration of advanced AI and machine learning capabilities into cobots. These technologies are enabling:

– More accurate predictive maintenance

– Enhanced adaptability to changing production environments

– Improved decision-making capabilities in complex tasks

2. Expanding Applications for Cobots

Cobots are no longer limited to simple, repetitive tasks. In 2024, we’re seeing cobots taking on more sophisticated roles:

– Quality control and inspection using advanced computer vision

– Complex assembly tasks requiring fine motor skills

– Collaborative research and development projects

3. Increased Payload Capacity and Reach

The latest cobot models are becoming larger and more powerful, with higher payload capacities and longer reach. This trend is opening up new applications in industries that previously relied solely on traditional industrial robots.

4. Enhanced Safety Features

Safety remains a top priority in human-robot collaboration. The latest cobots feature:

– Advanced sensor technologies for improved collision detection

– Sophisticated force-limiting capabilities

– Intuitive programming interfaces for easier safety configuration

5. Integration with IoT and IIoT

Cobots are becoming key components of the Industrial Internet of Things (IIoT):

– Real-time data collection and analysis for process optimization

– Seamless integration with other smart factory systems

– Enhanced remote monitoring and control capabilities

6. Mobile Cobots

The combination of cobots with autonomous mobile robots (AMRs) is creating a new category of flexible automation solutions:

– Increased flexibility in factory layouts

– Improved efficiency in logistics and material handling

– Enhanced adaptability to changing production needs

7. User-Friendly Programming and Interfaces

As cobots become more widespread, manufacturers are focusing on making them easier to program and operate:

– Intuitive drag-and-drop programming interfaces

– Augmented reality (AR) for simplified robot teaching and operation

– Natural language processing for voice-controlled cobot interactions

8. Sustainability and Energy Efficiency

Environmental considerations are driving innovations in cobot design:

– Energy-efficient motors and control systems

– Use of sustainable materials in cobot construction

– Optimization algorithms for reduced energy consumption

9. Customization and Modularity

The trend towards mass customization in manufacturing is reflected in cobot design:

– Modular cobot systems that can be easily reconfigured

– Customizable end-of-arm tooling for specific applications

– Scalable solutions that grow with the manufacturer’s needs

10. Collaborative Robot as a Service (CRaaS)

Following the trend of robotics as a service, some manufacturers are offering collaborative robots on a subscription basis:

– Reduced upfront costs for small and medium-sized enterprises

– Regular updates and maintenance included in the service

– Flexibility to scale robot usage based on demand

Conclusion

The collaborative robotics landscape in 2024 is characterized by increased intelligence, flexibility, and ease of use. As these technologies continue to evolve, they’re opening up new possibilities for manufacturers of all sizes to enhance their productivity, improve product quality, and create safer work environments.

At ChiJay Infrastructure Solutions, we’re committed to helping our clients navigate this exciting technological landscape. Whether you’re looking to implement your first cobot or expand your existing robotics capabilities, we’re here to provide expert guidance and support.

Are you ready to explore how collaborative robots can transform your manufacturing operations? Contact ChiJay Infrastructure Solutions today to learn how we can help you leverage these cutting-edge technologies for enhanced productivity and competitiveness in 2024 and beyond.